Automated Vision Inspection And Hand Sorting

Slidematic utilizes state-of-the-art automated sorting methods in addition to our manual inspection capabilities to ensure the highest level of customer satisfaction.

Our Internal Inventory Control & Processing Services Guarantee Precision Results

Due to our customers’ demand for 100% quality, Slidematic audited our outside vision sorting contractors in 2012. We determined for continuous improvement, that we would increase our internal vision sorting capacity as well as expand our capabilities.

After completing the audit in the following 3 years, Slidematic invested in eight Automated Vision Inspection Machines. We simultaneously converted the majority (over 95%) of our vision sorted parts to our internal processes.

With BILLIONS of parts sorted, we have not had a defect reach our customers with an inspected dimension.

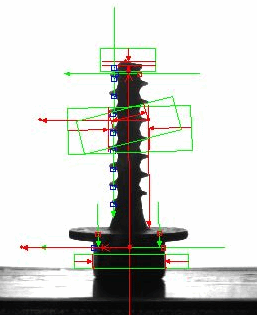

Outfitted With Telecentric Vision Sorting Technology

A majority of our machines incorporate telecentric lenses for the highest accuracy. Along with the latest in PC Hardware and our highly customizable software, we can sort for nearly every dimensional feature of your part.

Some of the most basic inspections involve lengths (Overall, Under Head, Head Height) and diameters (Head, Major, Minor, Patch Verification). We also can verify Helix Angle, Punch Penetration and other features based on the geometry of the part.

Precision Equipment Inspection Via Boundary Sampling

Slidematic also has a rigorous boundary sample program in place that verifies our equipment at predetermined time intervals. Real part samples are created that represent the upper and lower control limits to use during the Automated Vision Inspection process. Results of the boundary sample tests become tied to the Lot Number.

Don’t See What You’re Looking For?

For More Information or A Quotation.