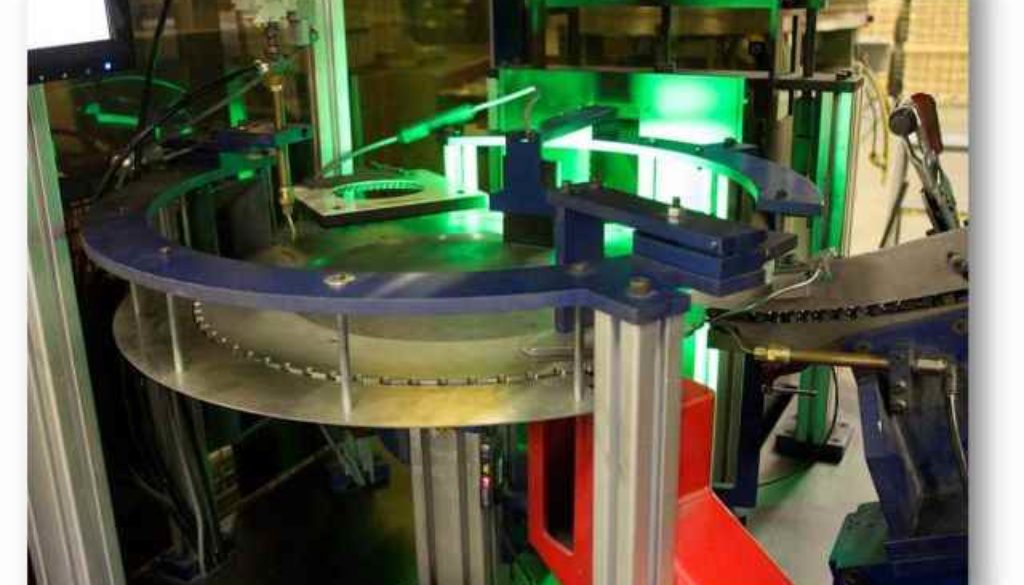

Vision Sorting

Starting with one vision sorter in 2012, Slidematic has expanded to a total of nine machines and brought in-house a majority of our sorting business, most of which is final inspection before being packaged, received into finished goods and shipped per customer releases.

To date, we have sorted over 300 Million Bolts, Nuts, and Screws with ZERO defects reaching the customer on an inspected dimension. This is an achievement we are very proud of and is due to our great employees and continuous investment in improved hardware to guarantee the best inspection possible. A majority of our machines incorporate telecentric lenses for the highest accuracy. All of them also feature the latest in industrial embedded PCs with Dual or Quad Core processors to allow for high-speed operation without compromising quality. They also tie into our ERP (Enterprise Resource Planning) software for logging the first piece approval at the beginning of the job, boundary samples throughout the job and the closing of the job before it is put into stock or sent to the customer.

As always, if you have further questions get in contact with us; we would be happy to explain how this service ties in with your parts to keep your lines up and running with increased quality.